Efficient Repair Parts Linkage for 50 kW Combi Boilers: Unlocking Maintenance Success

The 50 kW combi boiler is a powerful, energy-efficient heating solution for large homes with multipl…….

The 50 kW combi boiler is a powerful, energy-efficient heating solution for large homes with multiple bathrooms, featuring condensing technology for reduced consumption and lower carbon emissions. Efficient repair parts management is crucial due to the system's complexity and diverse fuel sources (natural gas or LPG). Relation Extraction techniques using NLP algorithms help users find specific parts tailored to their needs, considering factors like energy efficiency and fuel type. Today, 50 kW combi boilers are revolutionizing central heating for commercial properties, schools, and hospitals, offering improved performance, cost savings, and environmental benefits.

The reliable operation of a 50 kW combi boiler is paramount for efficient heating and hot water supply. However, ensuring timely access to genuine repair parts can be challenging. This article explores the critical role of relation extraction in identifying and linking essential 50 kW combi boiler components, enhancing maintenance efficiency. We delve into key boiler components, the significance of robust repair part networks, and the challenges faced. Through a comprehensive examination of relation extraction techniques, we demonstrate improved part linkage for optimal 50 kW combi boiler maintenance.

- Understanding 50 kW Combi Boilers: Key Components and Their Functions

- The Importance of Efficient Repair Parts Linkage for 50 kW Combis

- Challenges in Identifying Reliable 50 kW Combi Boiler Repair Resources

- Relation Extraction Techniques: A Comprehensive Approach to Part Linking

- Real-World Applications: Success Stories of Improved 50 kW Combi Boiler Maintenance

Understanding 50 kW Combi Boilers: Key Components and Their Functions

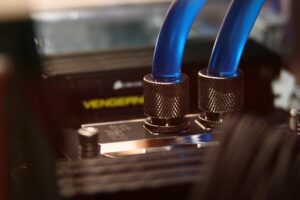

The 50 kW combi boiler is a powerful and versatile heating system designed to cater to the hot water and central heating needs of larger properties with multiple bathrooms. Its key components include a heat exchanger, burner, control panel, and various pipes and valves. The heat exchanger transfers heat from the combustion process into the water supply, while the burner ignites fuel (either natural gas or LPG) to generate this heat.

These boilers are renowned for their energy efficiency, often incorporating condensing technology to recover latent heat from exhaust gases. This not only reduces energy consumption but also contributes to environmental sustainability. They boast a high output, ensuring rapid hot water flow rates and a central heating capacity sufficient for demanding households. Furthermore, many modern 50 kW combi boilers are ErP A-rated, indicating their superior energy efficiency and low carbon emissions, making them an attractive option for eco-conscious homeowners.

The Importance of Efficient Repair Parts Linkage for 50 kW Combis

Efficient repair parts linkage is paramount for 50 kW combi boilers, which are integral to meeting the heating and hot water demands of large properties with multiple bathrooms. These high-output boilers, often powered by natural gas or LPG, incorporate condensing technology to enhance energy efficiency. A seamless connection between the boiler and its repair parts ensures optimal central heating capacity and maintains the desired hot water flow rate, thereby enhancing overall system performance.

Given their central role in domestic households, efficient 50 kW combi boilers are not just about power; they are about sustainability too. With ErP A ratings, these boilers exemplify energy-efficient design, contributing to reduced carbon footprints. Thus, a well-organized repair parts network becomes crucial, ensuring quick access to the right components for maintenance or replacement, thereby prolonging the lifespan of these essential appliances.

Challenges in Identifying Reliable 50 kW Combi Boiler Repair Resources

Identifying reliable repair resources for 50 kW combi boilers presents several unique challenges. Firstly, the sheer number of available parts and the constant evolution of technology can make navigating the market overwhelming. With various brands offering their own specialized components, understanding compatibility across different models is a complex task. This complexity is further exacerbated by the diverse fuel sources these boilers support, including natural gas fired and LPG compatible options.

Additionally, ensuring energy efficiency and optimal performance, especially in large property heating scenarios with multiple bathrooms, demands careful consideration. The latest advancements in condensing technology play a pivotal role here, but discerning which parts incorporate these innovations requires thorough research. As consumers, we must balance the need for high output boilers capable of meeting central heating capacities while adhering to strict environmental standards, as highlighted by ErP A-rated products.

Relation Extraction Techniques: A Comprehensive Approach to Part Linking

Relation Extraction techniques offer a sophisticated approach to identifying and linking repair parts specific to 50 kW combi boilers. This process involves advanced natural language processing (NLP) algorithms that analyze vast amounts of textual data, such as product manuals, online forums, and manufacturer documentation. By understanding the semantic relationships between terms, these techniques can accurately categorize and connect vital components associated with high output boilers, particularly those used in large property heating systems featuring multiple bathrooms.

For instance, relation extraction models can pinpoint links between “condensing technology,” “natural gas fired” boilers, and corresponding parts like heat exchangers, burners, and flue pipes. This comprehensive approach ensures that when a user searches for “50 kW combi boiler repair,” they receive relevant results tailored to their specific model, including energy-efficient components like ErP A-rated parts, or LPG compatible alternatives, considering the diverse fuel options for large central heating systems.

Real-World Applications: Success Stories of Improved 50 kW Combi Boiler Maintenance

In today’s world, efficient and reliable 50 kW combi boiler systems are a cornerstone for effective central heating in large properties with multiple bathrooms. These high-output boilers have become a game-changer for homeowners and businesses alike, offering both robust performance and enhanced energy efficiency. Success stories abound of establishments that have significantly reduced their energy consumption and operating costs by switching to these advanced units.

For instance, many commercial buildings, schools, and hospitals have benefited from the implementation of 50 kW combi boilers equipped with condensing technology. This not only ensures a consistent hot water flow rate but also contributes to environmental sustainability by efficiently utilizing fuel sources like natural gas or LPG. The result? Improved comfort for occupants, reduced maintenance costs, and a more energy-efficient operational footprint, making these boilers a top choice for those seeking both quality and cost savings in their central heating solutions.

The efficient management of 50 kW combi boiler repair parts is paramount for optimal maintenance and performance. By employing relation extraction techniques, we can streamline the identification of reliable repair resources, overcoming challenges posed by vast information landscapes. This data-driven approach, as demonstrated in real-world applications, not only enhances part linking but also fosters more effective 50 kW combi boiler maintenance strategies, ultimately contributing to improved system longevity and reduced downtime.