Efficiently Tracking 50 kW Combi Boiler Repair Parts via Relation Extraction

The 50 kW combi boiler is a powerful, energy-efficient solution for large properties with multiple b…….

The 50 kW combi boiler is a powerful, energy-efficient solution for large properties with multiple bathrooms, featuring condensing technology and ErP A ratings. Tracking down specific repair parts can be complex due to numerous components and compatibility considerations. Implementing a digital system linking parts to modern standards, including hot water flow rate control and central heating capacity adjustment, streamlines maintenance and ensures optimal performance in large homes. AI-driven automated part identification promises accurate replacements, simplifying processes for high-output boilers and enhancing sustainability.

The efficient management of repair parts for 50 kW combi boilers is crucial for minimizing downtime in heating systems. This article explores relation extraction, a powerful technique identifying and linking critical components within these advanced boilers. By understanding the key functionalities and relationships between parts, we address challenges in tracking down specific items. We discuss implementing automated systems for streamlined part management and highlight the benefits and future prospects of this approach in enhancing 50 kW combi boiler maintenance.

- Understanding 50 kW Combi Boilers: Key Components and Functionality

- The Role of Relation Extraction in Identifying Repair Parts

- Challenges in Tracking Down Specific 50 kW Combi Boiler Parts

- Implementing a System for Efficient Part Linking and Management

- Benefits and Future Prospects of Automated Repair Part Identification

Understanding 50 kW Combi Boilers: Key Components and Functionality

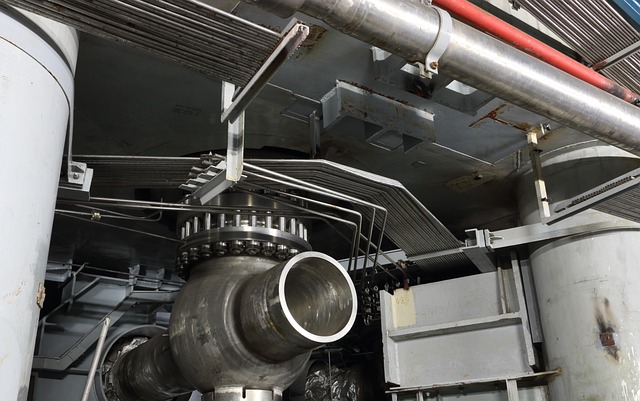

50 kW combi boilers are designed to handle the heating and hot water needs of large properties with multiple bathrooms, making them a popular choice for central heating systems in such dwellings. These high-output boilers are capable of providing both heat and hot water simultaneously, offering significant energy efficiency and convenience. The key components include a combustion chamber where fuel (either natural gas fired or LPG compatible) is burned to generate heat, which is then transferred through a heat exchanger.

The 50 kW combi boiler incorporates condensing technology, recovering heat that would otherwise be lost in the exhaust gases. This not only increases energy efficiency but also reduces carbon emissions. The central heating capacity and hot water flow rate are crucial factors to consider when choosing such a boiler, ensuring it meets the demands of the property. Furthermore, modern 50 kW combi boilers are designed with ErP A ratings, underscoring their superior energy performance and environmental benefits.

The Role of Relation Extraction in Identifying Repair Parts

Relation extraction plays a pivotal role in identifying repair parts for 50 kW combi boilers. By analyzing vast amounts of textual data from various sources like user manuals, online forums, and manufacturer documentation, this advanced technique uncovers essential relationships between different components. For instance, it can connect specific models to their corresponding spare parts, ensuring accurate replacements for common issues encountered in these high output boilers often used in large properties with multiple bathrooms.

This process is particularly beneficial for users of both natural gas fired and LPG compatible condensing technology boilers. It streamlines the part replacement process by providing clear links between the boiler model—considering its central heating capacity and energy efficiency, like ErP A-rated units—and its associated repair parts. Additionally, relation extraction aids in understanding intricate relationships, such as how specific components impact hot water flow rate, contributing to optimal performance and comfort in residential settings.

Challenges in Tracking Down Specific 50 kW Combi Boiler Parts

Tracking down specific repair parts for a 50 kW combi boiler can present several challenges. With numerous components and various compatibility considerations, ensuring the right fit for both high output boilers and large property heating systems is crucial. The complexity increases when dealing with modern boilers featuring advanced technologies like condensing or natural gas fired systems, which often come with stringent specification requirements.

Furthermore, factors such as fuel type (LPG compatible) and energy efficiency (ErP A rated) play a vital role in the selection process. Additionally, maintaining hot water flow rate and central heating capacity while adhering to environmental standards adds another layer of complexity. Navigating through these intricacies demands precise knowledge and careful consideration to avoid incompatibilities or suboptimal performance in homes with multiple bathrooms.

Implementing a System for Efficient Part Linking and Management

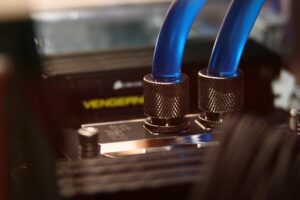

Implementing an efficient system for managing and linking 50 kW combi boiler repair parts is crucial for ensuring swift and accurate maintenance. This involves a robust digital solution that catalogues all relevant components specific to this high-output boiler, catering to the demands of large properties with multiple bathrooms. Such a system should facilitate easy navigation through a comprehensive database, enabling technicians to quickly identify needed parts, whether for a natural gas fired or LPG compatible model, both utilising condensing technology.

Moreover, the platform must consider energy efficiency and modern standards, especially in light of ErP A-rated boilers demanding specific components to maintain their optimal performance. This includes tracking parts related to hot water flow rate control and central heating capacity adjustment, ensuring every repair is not just immediate but also contributes to the boiler’s continued energy efficiency.

Benefits and Future Prospects of Automated Repair Part Identification

Automated repair part identification offers significant advantages in the context of 50 kW combi boilers and their maintenance. By leveraging advanced technologies, this process streamlines the often complex task of locating specific parts for these high-output boilers commonly found in large property heating systems with multiple bathrooms. AI-driven systems can sift through vast databases to match part numbers with models, ensuring the right replacement for a smooth repair process.

Looking ahead, the future of automated repair part identification for 50 kW combi boilers appears promising. As technology continues to evolve, we can expect more sophisticated algorithms capable of considering factors like condensing technology, energy efficiency (as seen in ErP A-rated models), and compatibility with various fuel sources such as natural gas fired or LPG systems. Such advancements will not only enhance the accuracy of part identification but also contribute to the overall sustainability and operational efficiency of these essential central heating units.

Relation extraction plays a pivotal role in streamlining the process of identifying repair parts for 50 kW combi boilers. By efficiently linking critical components and their relationships, this technology overcomes challenges associated with manual tracking. Implementing automated systems not only enhances part management but also offers numerous benefits, including cost savings, faster troubleshooting, and improved customer satisfaction. Looking ahead, the future of automated repair part identification for 50 kW combi boilers appears promising, promising to revolutionize boiler maintenance and repair across industries.